Fulcrum Returns to Trail Riding with Metal Carbon and ALX Wheels

Lesezeit: 3 – 4 Minuten

As Fulcrum celebrates two decades of wheel-building excellence, the iconic Italian brand sets a bold new standard with its Metal Carbon and Metal ALX wheelsets — engineered for demanding trail riders who value a perfect balance of durability, precision, and real-world performance.

After establishing dominance in XC racing with the RED ZONE series and their Olympic pedigree, Fulcrum is officially back for trail and enduro riding demands – for classic and e-MTBs. Learn more about the Fulcrum philosophy and the Metal wheelsets.

Designed in Italy. Built in Europe. Tested Everywhere.

Fulcrum’s approach to MTB wheels doesn’t chase extremes in weight or flash — it chases longevity, ride quality, and control. The development of Metal Carbon and Metal ALX took place under Fulcrum’s meticulous R&D program in Vicenza, Italy, with prototyping and testing led entirely in-house, and mass production executed in their own facility in Romania. The company, with over 1,000 employees shared with Campagnolo, refuses to compromise on EU-based quality control.

The result? Two wheelsets — one carbon, one alloy — built not to be the lightest, but to be the most reliable and best performing trail wheels in their category.

Metal ALX vs. Metal Carbon

Testing That Goes Beyond Certification

Fulcrum puts every wheel through an exhaustive five-phase testing program:

Lab Testing: High-load simulations that exceed ASTM Category 4 requirements.

Durability Cycling: Tens of thousands of kilometers logged by pro teams like Buff-Megamo and Speed Company Racing.

Real-World Testing: Trails, races, and everything in between — under elite and amateur riders.

Environmental Stress Testing: UV exposure, salt spray, mud immersion, pressure washer cycles — nothing is left to chance.

Aesthetic Endurance: Even the graphics undergo abrasion and chemical resistance validation.

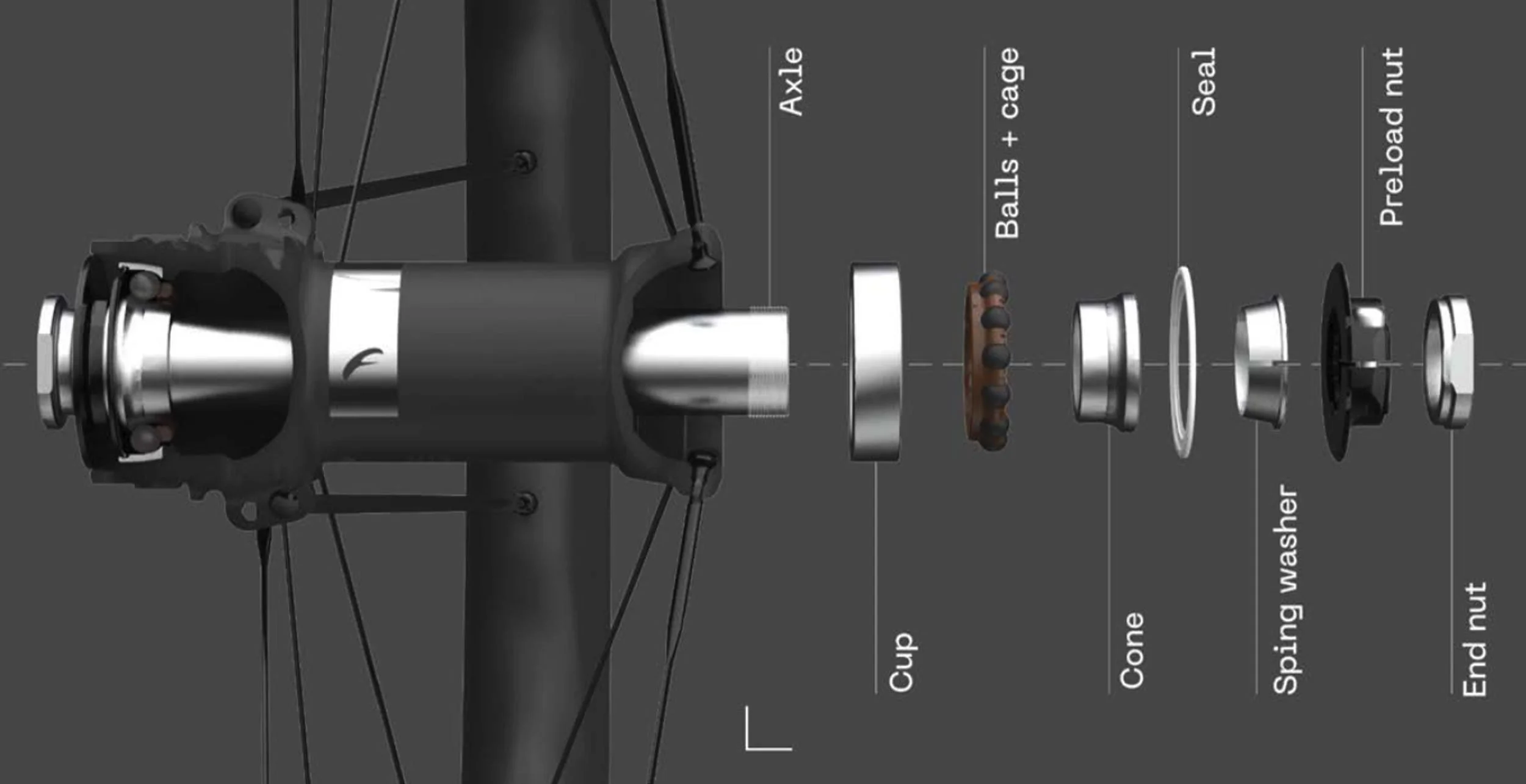

Inside the Hub: Real Axle Technology

Every Fulcrum hub features a solid axle system with ultra-tight tolerances, crafted from aerospace-grade aluminum. Unlike many competitors, Fulcrum avoids interchangeable adapters, focusing instead on perfect part alignment and a worry-free user experience. Combined with their triple engagement system for reliable drive under power (especially for E-MTB applications), the hubs are silent, smooth, and incredibly durable.

Metal Carbon

Fulcrum’s new Metal Carbon is a high-end carbon wheelset that blends precise trail handling with exceptional resilience. Weighing just 1,550 grams, it offers a 32mm internal rim width, optimized for 2.4"–2.6" tires — according to Fulcrum the sweet spot for aggressive trail riding.

Key Technical Features (Photos Below)

FF80 Carbon Layup: Fulcrum's proprietary mix of carbon fibers and resins, tuned for lateral stiffness and vertical compliance.

Nip(ple) Force Design: Dual asymmetrical rim (6mm/3.5mm offsets) for better spoke tension and impact management.

2-Way Fit™ Technology: Tubeless-ready without the need for rim tape thanks to the undrilled rim bed. Only the valve hole is drilled, preserving fiber integrity.

DSRC (Direct Rim-Spoke Coupling): Molded-in spoke seats isolate aluminum nipples from carbon to prevent galvanic corrosion.

Cup & Cone Bearings: Steel bearing system aligned with spoke entry angles to reduce stress and prolong service life. Fully serviceable and overhaul-friendly.

Non-Touching Spokes: Designed to avoid crossover contact, increasing long-term spoke tension stability and eliminating creaks.

Trail Ready, E-MTB Capable: Approved for E-MTB light use (max torque 60Nm, max system weight 125 kg) when used with steel freehub body.

Specs Summary

Weight: 1,550 g

Inner Width: 32 mm

Rim Height: 26.2 mm

Spokes: 24 F / 28 R

Price: € 1,640.00

Nip(ple) Force Design – the main advantage of this solution is a well balanced and reliable wheel, as well as greater resistance to stresses. This is achieved with a double asymmetry (6 mm on one side and 3.5 on the other).

Tubeless-ready without the need for rim tape thanks to the undrilled rim bed.

This is how the molded-in spoke seats look like.

They isolate aluminum nipples from carbon to prevent galvanic corrosion.

As the rim has no holes for inserting the nipples, the nipples are inserted into the nipple hole using this small magnetic tool – MoMag. The small screw is screwed into the nipple. The nipple is thrown through the valve hole into the rim. The magnet is placed on the rim from the outside, the magnet grabs the screw in the nipple, and the nipple is inserted into the nipple hole.

Cup & Cone bearings use inclined rings aligned with the axis of rotation to effectively handle riding forces. As the wheel spins, tension moves from the ground to the rim, through the spokes, and into the hub.

The spokes connect at an angle that aligns with the cone’s tilt, allowing forces to be properly absorbed by each component—ensuring optimal performance and long-term durability.

Metal ALX

While the Metal Carbon takes the premium crown, the Metal ALX hits a sweet spot for performance-oriented riders looking for an accessible, bombproof alloy wheelset with pro-level tech.

What Sets It Apart

6069-T6 Aluminum Rim: Lightweight yet tough, featuring a welded seam and square milled profile to reduce rotating mass without sacrificing strength.

30 mm Internal Width: Slightly narrower than the Carbon but still optimized for modern trail tires.

Refined Aesthetics: Laser-etched finish with Fulcrum’s new Form Function branding. Reflective decals and tactile graphics complete the look.

Cup & Cone Bearings: Shared with the carbon version — reliable, easily serviceable, and built for miles.

E-MTB Light Approved: Same system weight and torque limits as the Carbon version.

Designed to offer confidence-inspiring handling with a price-to-performance ratio few can match.

Specs Summary

Weight: 1,860 g

Inner Width: 30 mm

Rim Height: 18.6 mm

Spokes: 24 F / 28 R

Price: € 650.00

More Than a Wheelset – A Philosophy

Fulcrum doesn’t build wheels for spec sheet wars. They build them for performance on the trail, for ease of use, and for a long lifespan. Their engineers reject trends like carbon spokes or overly minimal hub systems if it means compromising durability or serviceability.

Their mission? „Ride more. Worry less.“

With the Metal Carbon and Metal ALX wheelset, Fulcrum wants to attack the trail and enduro segment. Technical transparency, EU-controlled production and a strong focus on ride feel and reliability are important to them. The wheels were designed for riders who can rely on their wheels without much care – every day on every trail.